Explore cutting-edge laser cutting techniques and innovations that are revolutionizing manufacturing precision and capabilities, including advanced beam control, multi-axis cutting, and hybrid processes.

Modern laser cutting systems employ sophisticated beam control methods:

1. Dynamic Beam Shaping: - Real-time mode adjustment - Adaptive focus control - Power distribution optimization - Multi-zone processing

2. Advanced Optics: - Adaptive optical systems - Beam quality enhancement - Wavefront correction - Focus position control

3. Pulse Control: - Ultra-short pulse processing - Burst mode operation - Temporal pulse shaping - Energy distribution control

Multi-axis cutting expands processing capabilities:

1. 5-Axis Systems: - Complex geometry cutting - Tube and profile processing - Bevel cutting capability - 3D part processing

2. Robotic Integration: - Flexible path planning - Complex part handling - Automated processing - Enhanced accessibility

3. Hybrid Systems: - Combined processes - In-process measurement - Adaptive control - Quality verification

Cutting-edge process developments include:

1. Remote Processing: - Scanner-based systems - High-speed processing - Large area coverage - Flexible beam delivery

2. Hybrid Technologies: - Laser-waterjet cutting - Laser-plasma processing - Multi-beam systems - Combined heat treatment

3. Smart Processing: - AI-based optimization - Real-time monitoring - Predictive control - Quality assurance

Advanced techniques for specific materials:

1. Composite Materials: - Layer-specific processing - Delamination prevention - Heat control strategies - Edge quality optimization

2. Advanced Alloys: - High-reflectivity processing - Thermal management - Oxidation prevention - Surface quality control

3. Specialized Materials: - Ceramic processing - Glass cutting advances - Polymer optimization - Multi-layer materials

Advanced quality control techniques:

1. In-Process Monitoring: - Real-time quality control - Defect detection - Process adjustment - Documentation systems

2. Edge Quality Control: - Surface roughness optimization - Kerf width control - Heat affected zone minimization - Dross prevention

3. Precision Enhancement: - Position accuracy improvement - Thermal compensation - Dynamic error correction - Calibration systems

Recent innovations include AI-driven process optimization, hybrid cutting systems combining multiple technologies, advanced beam shaping techniques, and real-time quality monitoring systems. These developments are improving precision, speed, and processing capabilities across various materials.

Multi-axis cutting systems enable complex 3D part processing, bevel cutting, and tube processing. They offer greater flexibility in part handling and can access difficult-to-reach areas, making them ideal for complex geometries and automated production.

Hybrid systems combine different cutting technologies to leverage their respective advantages. For example, laser-waterjet systems combine the precision of laser cutting with the cooling effects of water, enabling improved cutting quality and the ability to process heat-sensitive materials.

Learn essential safety practices for laser cutting operations.

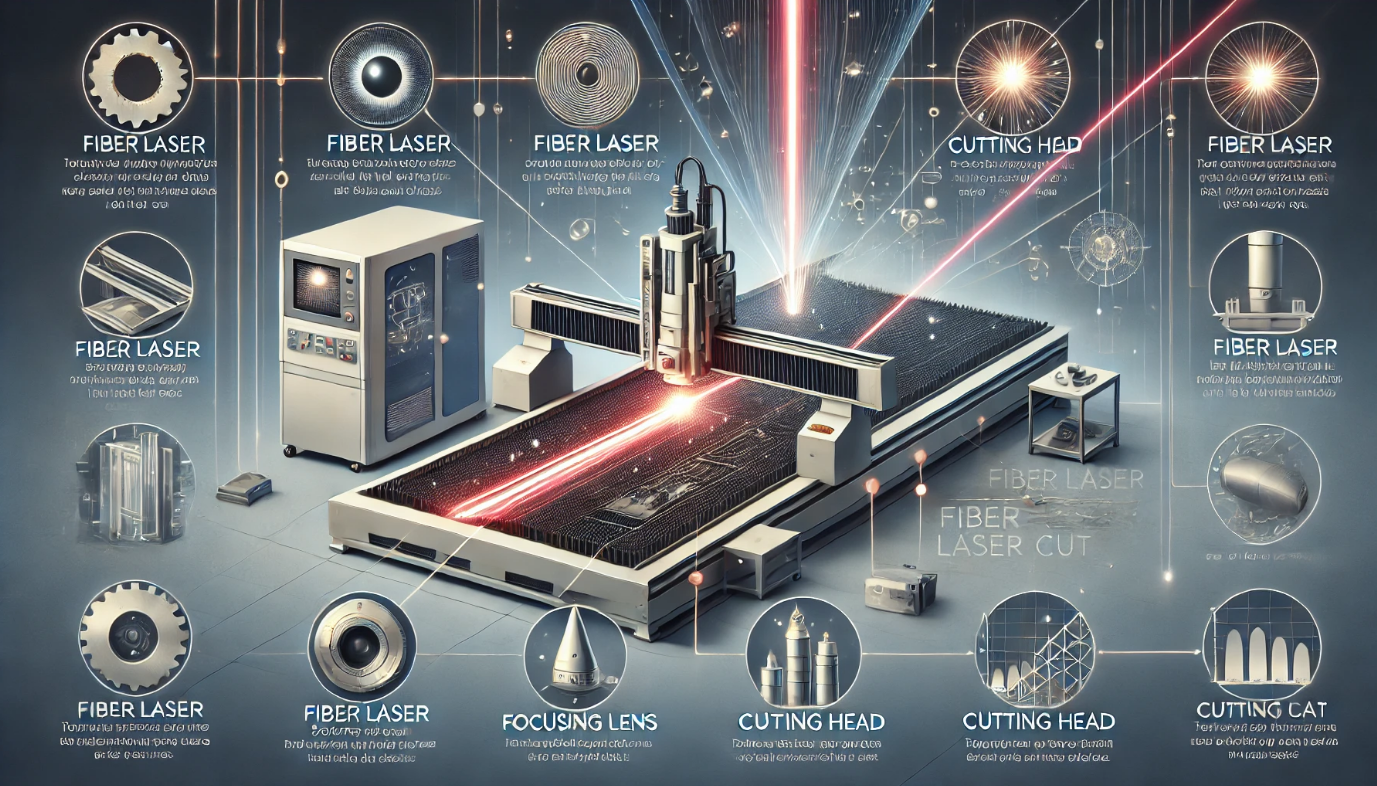

Explore the working principles of fiber laser cutting machines and their advanced technology.

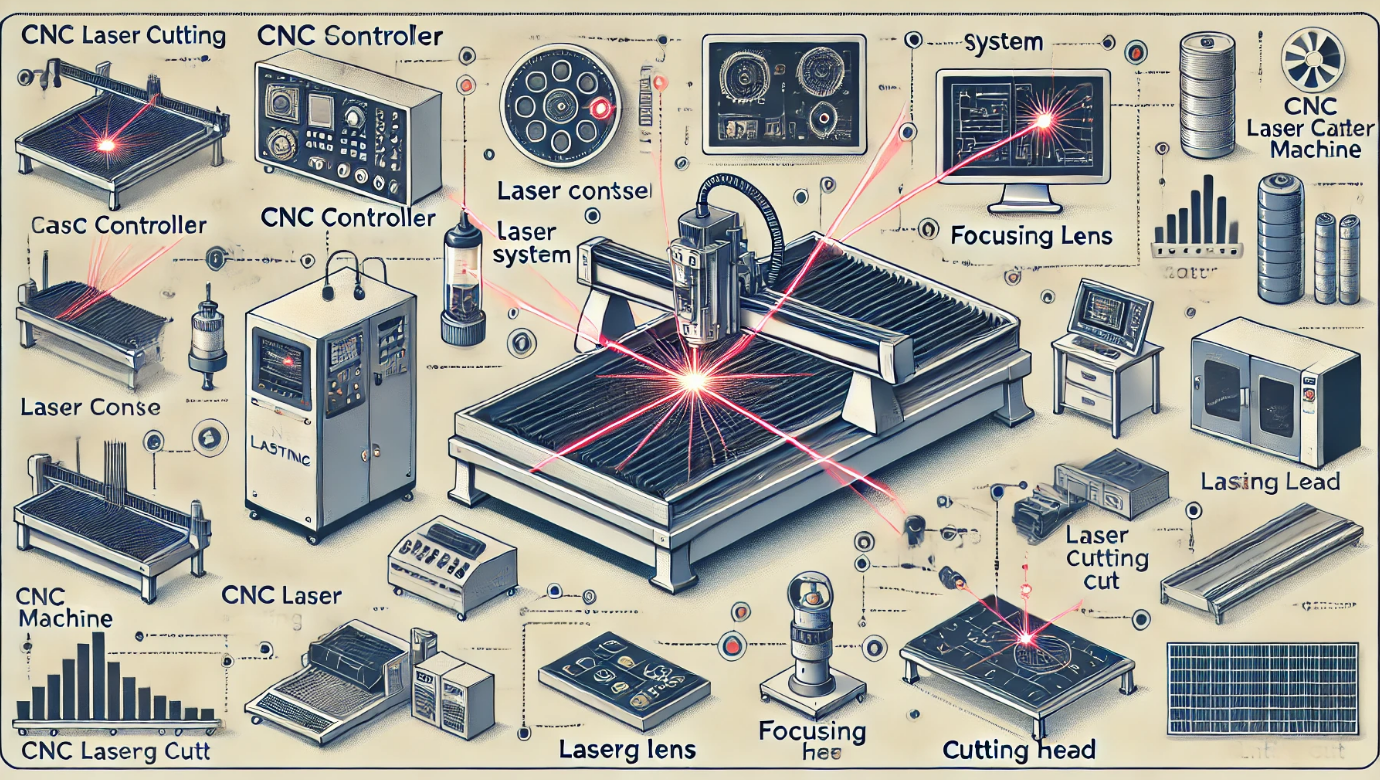

Understanding the complete workflow of CNC-controlled laser cutting systems.