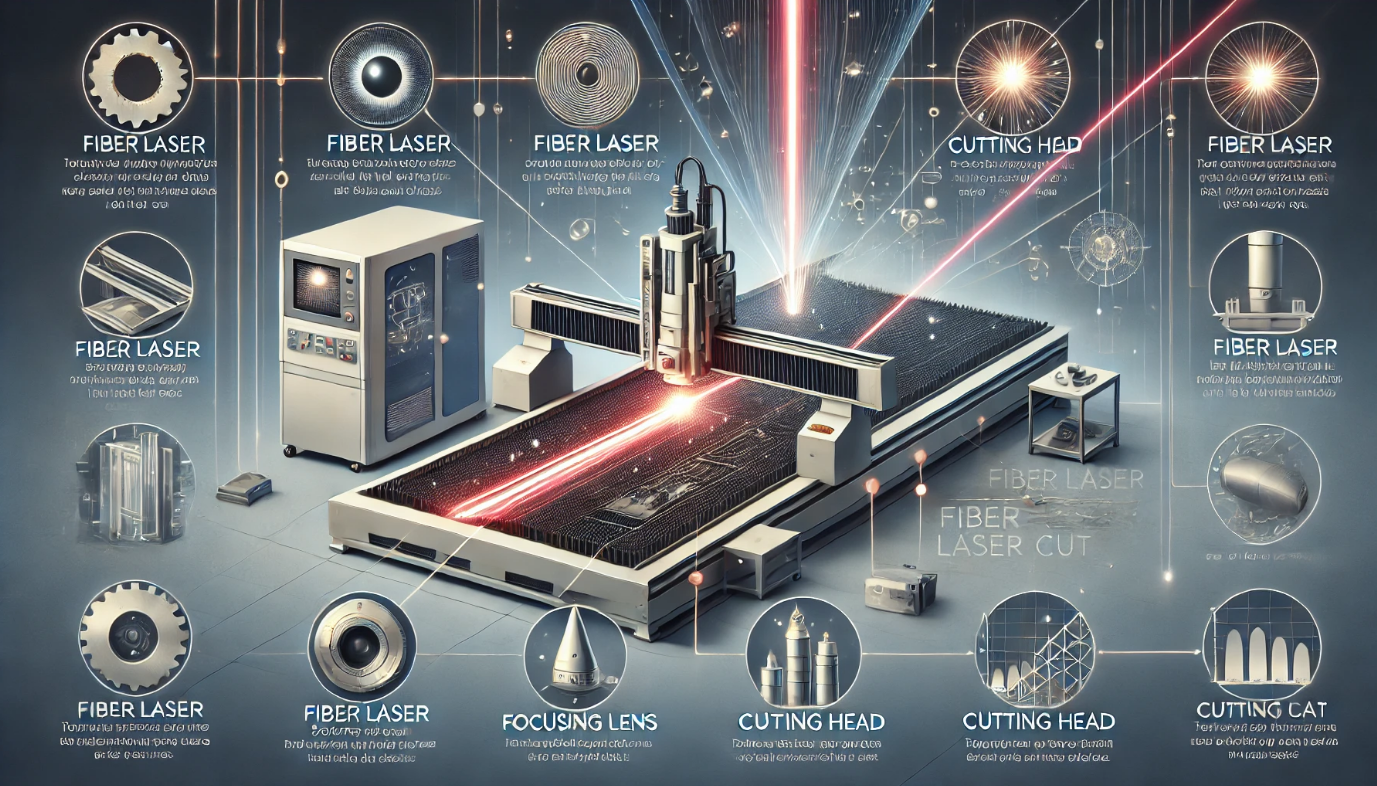

A comprehensive explanation of fiber laser cutting machine principles, components, and operational processes, focusing on the unique aspects of fiber laser technology.

Fiber laser cutting machines use a unique laser generation method:

1. Core Technology: - Fiber-optic cable doped with rare earth elements - Diode-pumped laser generation - 1064nm wavelength light emission - High beam quality and efficiency

2. Key Advantages: - Higher absorption by metals - Greater energy efficiency - Minimal maintenance requirements - Compact design and footprint

The fiber laser beam generation process involves several stages:

1. Pump Source: - Semiconductor diode lasers - Multiple diode arrays - Optical coupling system - Power supply control

2. Active Fiber: - Ytterbium-doped fiber core - Fiber Bragg gratings - Optical amplification - Beam conditioning

3. Beam Delivery: - Fiber optic cables - Collimating optics - Focusing system - Cutting head integration

The beam delivery system is crucial for performance:

1. Optical Components: - Collimating lenses - Focusing optics - Protective windows - Beam mode control

2. Cutting Head: - Precision focusing - Height sensing - Gas nozzle system - Collision protection

3. Process Monitoring: - Power monitoring - Focus position control - Cut quality sensors - Real-time adjustments

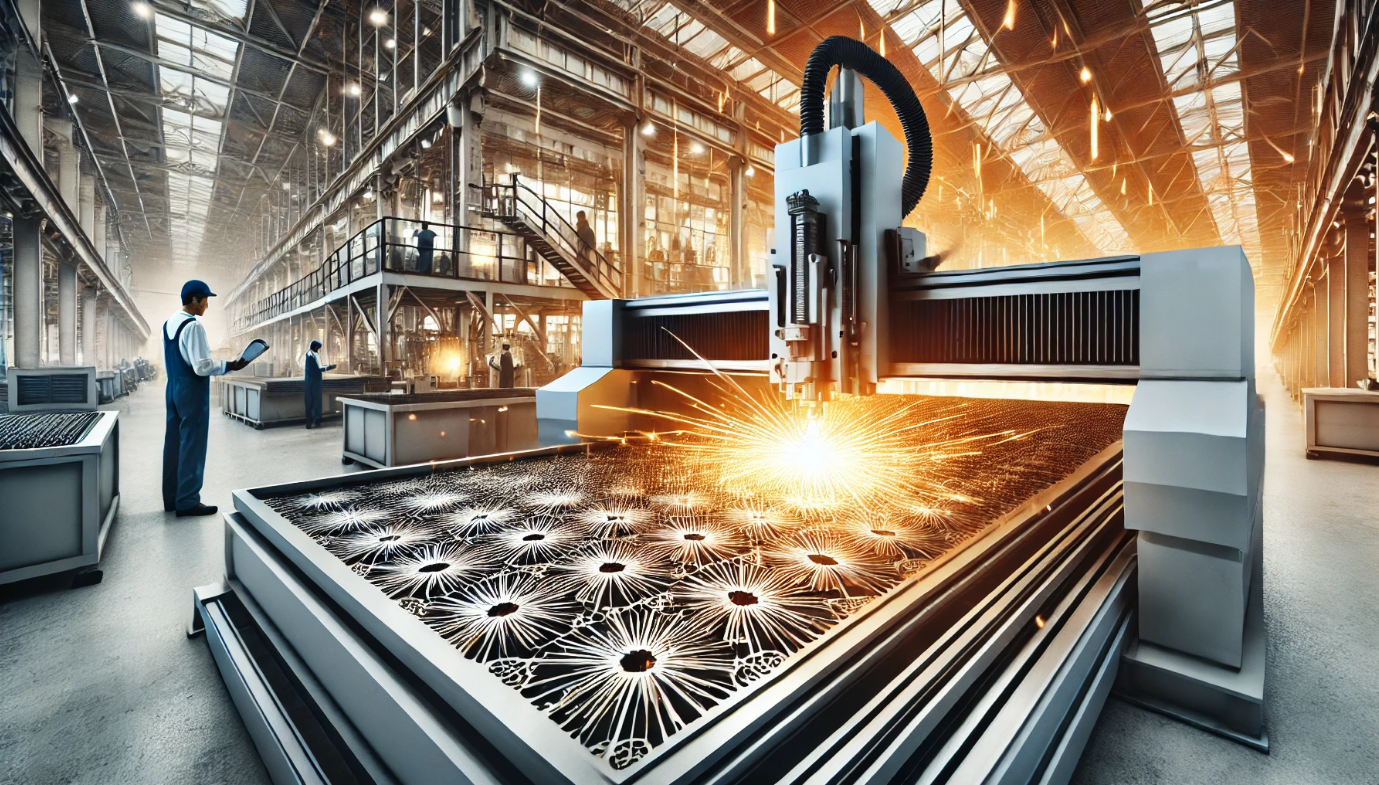

Fiber laser cutting involves specific material interactions:

1. Energy Absorption: - High absorption by metals - Rapid heat generation - Precise melting zone - Clean vaporization

2. Cutting Process: - Melt ejection - Oxidation assistance - Kerf formation - Edge quality control

3. Process Parameters: - Power density control - Cutting speed optimization - Focus position adjustment - Gas pressure regulation

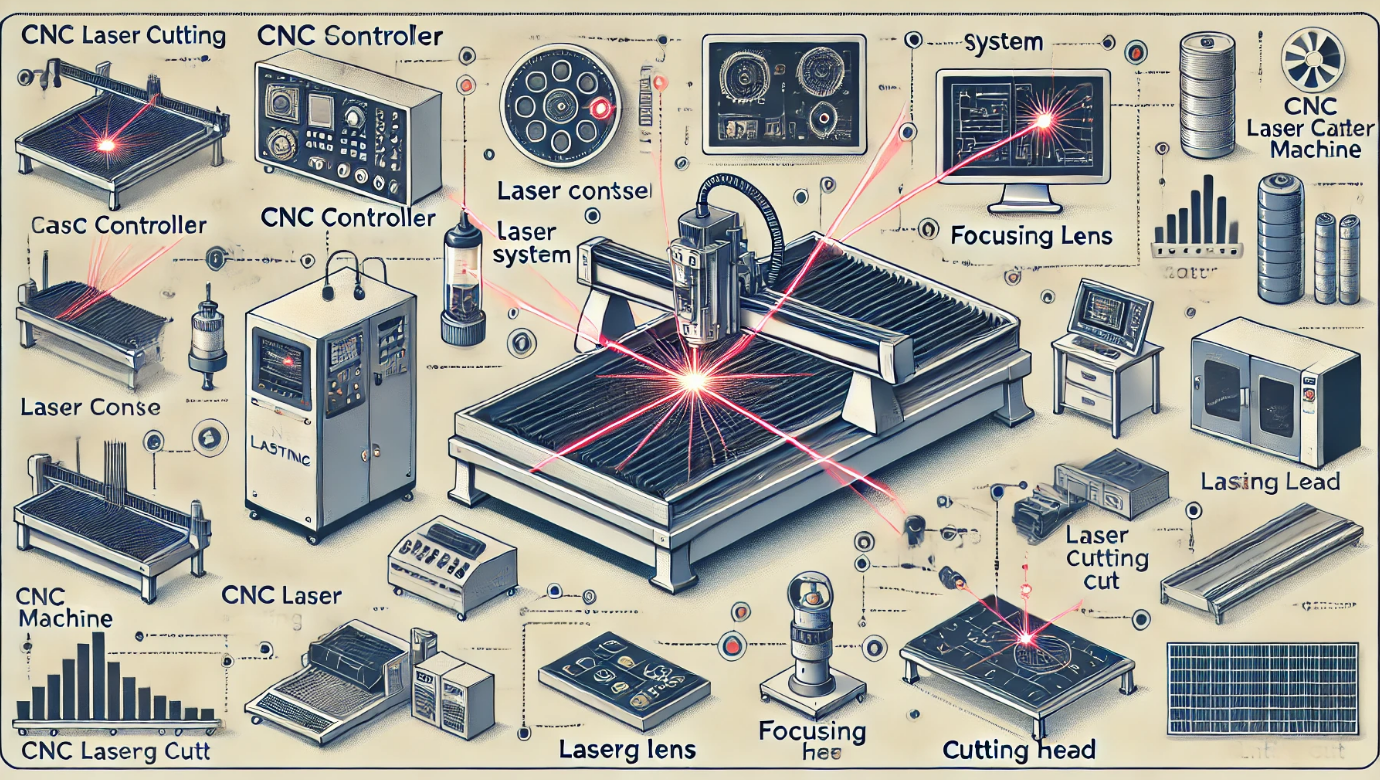

Modern fiber laser systems feature advanced control:

1. CNC Integration: - High-speed processing - Precise motion control - Dynamic power adjustment - Process optimization

2. Automation Features: - Automatic material handling - Nesting optimization - Production scheduling - Quality monitoring

3. Smart Functions: - Adaptive cutting - Parameter optimization - Process monitoring - Predictive maintenance

Fiber laser cutting offers distinct advantages:

1. Cutting Capabilities: - High-speed thin material cutting - Precise thick material processing - Reflective metal cutting - Fine feature capability

2. Quality Features: - Narrow kerf width - Minimal heat affected zone - Clean cut edges - High repeatability

3. Operational Benefits: - Low operating costs - High energy efficiency - Minimal maintenance - Long service life

Fiber lasers excel in various applications:

1. Material Range: - Carbon steel - Stainless steel - Aluminum - Copper - Brass - Other reflective metals

2. Industry Applications: - Automotive manufacturing - Aerospace components - Medical devices - Electronics industry - General fabrication

3. Special Processes: - High-speed cutting - Micro-cutting - Precision parts - Mass production

Fiber lasers use a fiber-optic delivery system and ytterbium-doped fiber as the lasing medium, resulting in higher efficiency, better beam quality, and superior performance on metals. They also offer lower operating costs, minimal maintenance, and longer service life compared to other laser types.

Fiber lasers excel at cutting metals, particularly reflective materials like aluminum, copper, and brass. They are especially effective for thin to medium-thickness materials, offering high-speed cutting with excellent edge quality. However, they may not be ideal for non-metallic materials.

Fiber laser cutting achieves high precision through several factors: a smaller focused beam diameter, superior beam quality, precise CNC control, and advanced focusing systems. This combination allows for narrow kerf widths, minimal heat affected zones, and highly accurate cuts.

Learn essential safety practices for laser cutting operations.

Discover advanced techniques in laser cutting technology.

Understanding the complete workflow of CNC-controlled laser cutting systems.