Comprehensive safety guidelines for laser cutting operations, covering personal protection, facility requirements, operational procedures, and emergency protocols.

Essential personal protective equipment and practices:

1. Eye Protection: - Wavelength-specific safety glasses - OD rating requirements - Proper fit and maintenance - Regular inspection protocols

2. Skin Protection: - Appropriate clothing requirements - Glove specifications - UV protection measures - Burn prevention

3. Respiratory Protection: - Fume exposure prevention - Filter requirements - Mask selection guidelines - Maintenance procedures

Facility safety considerations include:

1. Enclosure Systems: - Class-specific requirements - Interlock systems - Viewing windows - Access control

2. Ventilation Systems: - Fume extraction requirements - Filter specifications - Airflow monitoring - Maintenance schedules

3. Fire Safety: - Fire detection systems - Suppression equipment - Emergency procedures - Regular testing

Safe operating procedures include:

1. Pre-operation Checks: - System verification - Safety system testing - Material inspection - Area clearance

2. Operating Protocols: - Start-up procedures - Monitoring requirements - Parameter verification - Emergency response

3. Maintenance Safety: - Lock-out procedures - Service protocols - Testing requirements - Documentation needs

Material-specific safety measures:

1. Material Hazards: - Toxic material identification - Reflectivity concerns - Flammability issues - Chemical reactions

2. Material Handling: - Safe loading procedures - Storage requirements - Waste disposal - Spill response

3. Process Safety: - Parameter limits - Monitoring requirements - Quality checks - Emergency procedures

Emergency response protocols:

1. Emergency Response: - Shutdown procedures - Evacuation routes - First aid measures - Reporting requirements

2. Incident Management: - Response procedures - Documentation requirements - Investigation protocols - Corrective actions

3. Training Requirements: - Emergency response training - Regular drills - Certification needs - Update procedures

Essential safety features include proper enclosure systems with interlocks, appropriate ventilation and fume extraction, emergency stop systems, proper beam containment, and personal protective equipment including wavelength-specific eye protection and appropriate clothing.

Safety training should be conducted initially for all new operators, with refresher training at least annually. Additional training should be provided when new equipment is installed or procedures are updated. Emergency response drills should be conducted quarterly.

Key material safety considerations include proper material identification and handling, understanding potential hazards such as toxic fumes or reflectivity issues, proper storage and disposal procedures, and having appropriate emergency response protocols for material-specific incidents.

Discover advanced techniques in laser cutting technology.

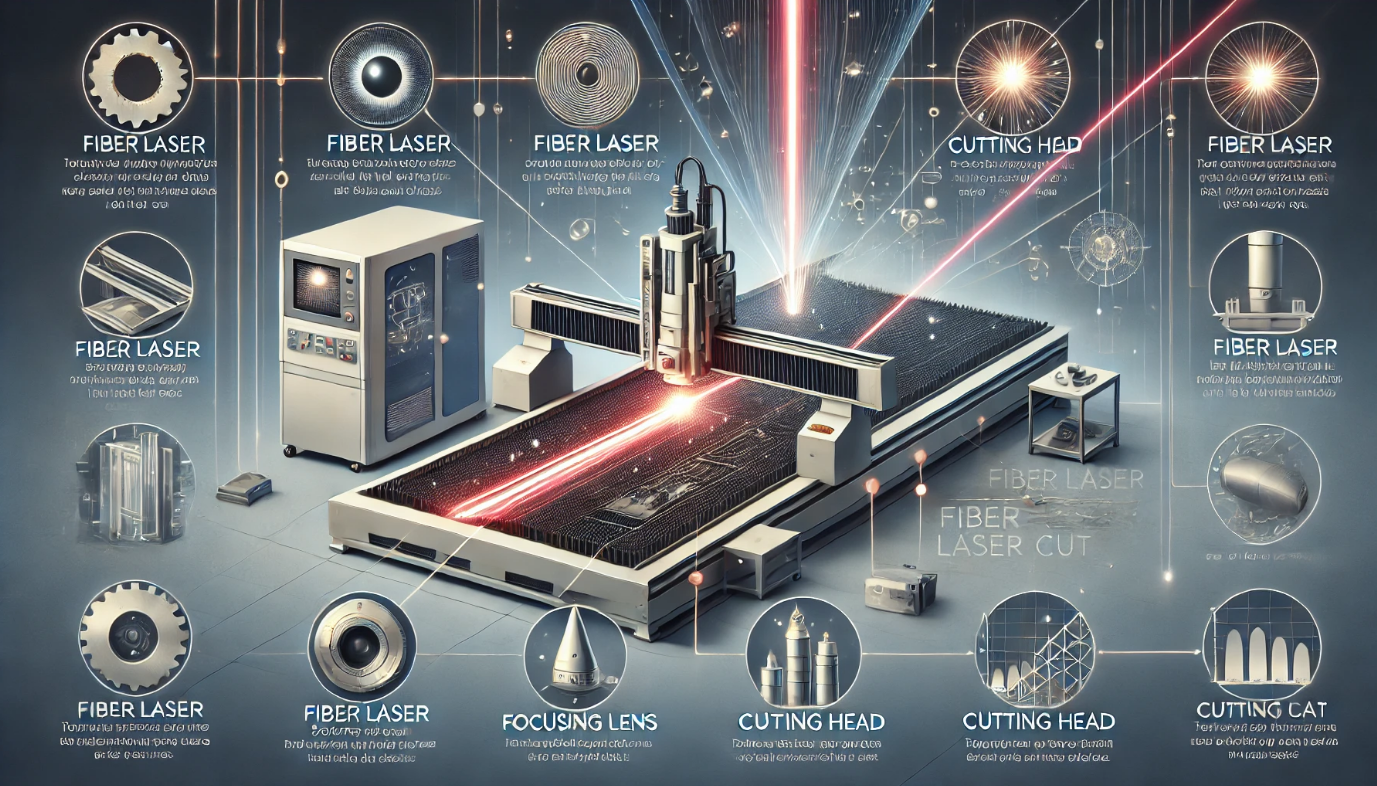

Explore the working principles of fiber laser cutting machines and their advanced technology.

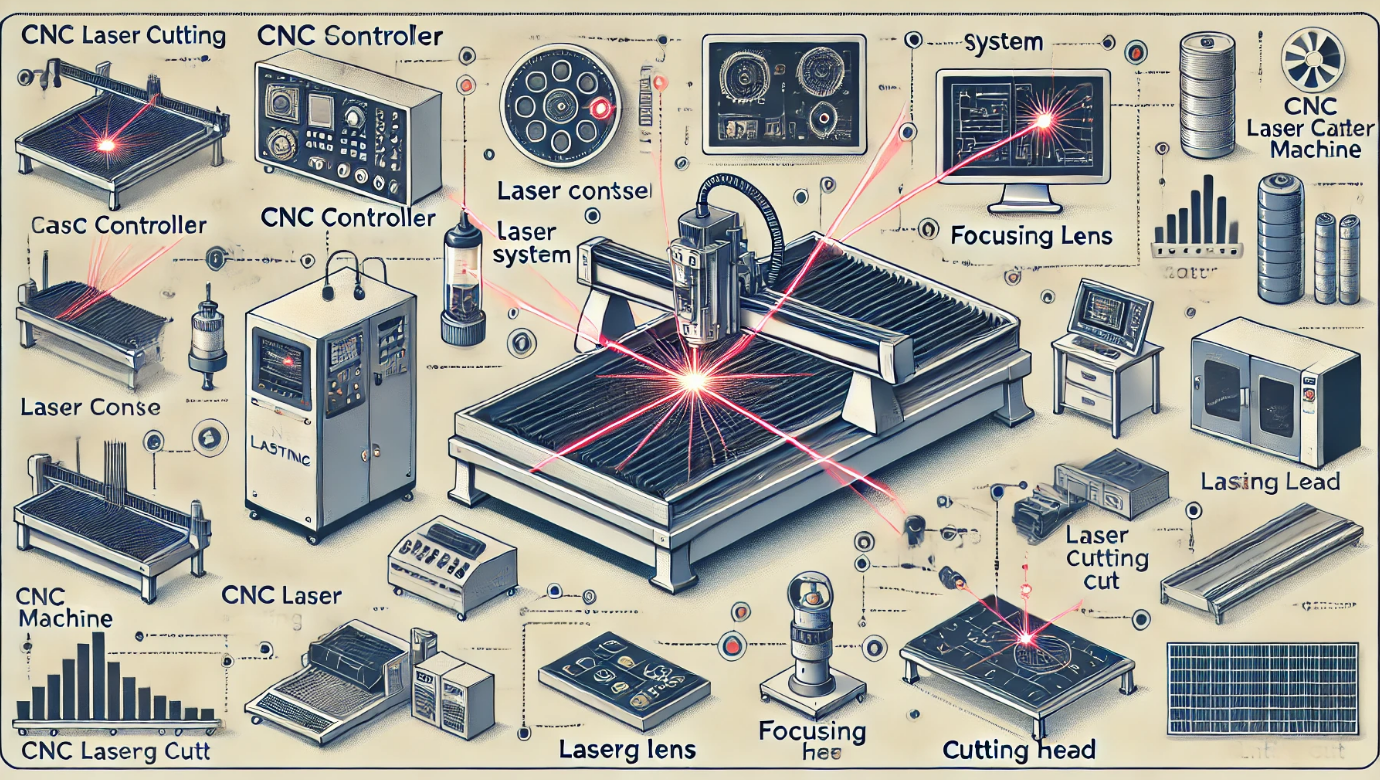

Understanding the complete workflow of CNC-controlled laser cutting systems.